| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | Huihua |

| Price : | Negotiable |

| Payment Terms : | T/T |

| Supply Ability : | 100t/year |

| Delivery Time : | no limit |

Lithium ion Battery Tabs/ Aluminium and Nickel Tabs for Battery Connector

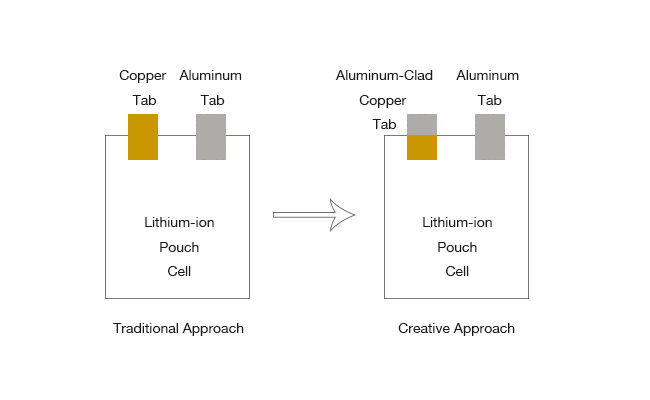

The aluminum-clad copper material tab provides a low cost and high-performance solution for li-ion battery tab joining. Nowadays, the leads or tabs from Li-ion pouch and prismatic cells are often configured with one lead of copper and the other lead of aluminum. This brings a challenge for welding copper to aluminum with the busbar. By replacing one of the leads with an aluminum-clad copper tab, the busbar joining can be applied to all aluminum to aluminum connections. This greatly simplifies the welding process.

| Thickness | 0.010 – 0.150 mm |

| Width | 1.0 – 10 mm |

| Customization | Custom dimensions for thickness and width can be produced on request |

Wound on spools or plastic core with side shields

Q: Are you trading or manufacturer ?

A: We are company,and we have our own factory

Q: How long is your delivery time?

A: Generally it is 2-3 days if the goods are in stock. or it is 5-7

days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay

the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30%

T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us

|