| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | Huihua |

| Price : | Negotiable |

| Payment Terms : | T/T |

| Supply Ability : | 100t/year |

| Delivery Time : | no limit |

| Parameter table | |

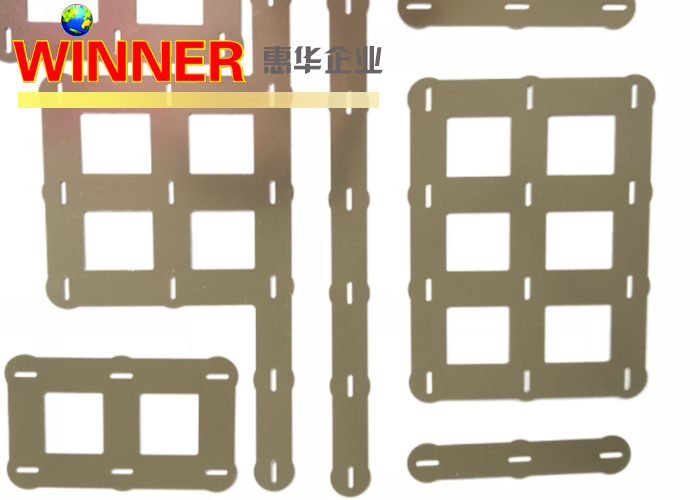

| Product name | Advantages of Power Battery 18650 Combination Solution |

| Specifications | Customized processing |

| physical property | Good spot welding effect and lower internal resistance |

| Texture of material | Pure nickel, nickel plating |

| Packaging method | Packing in bulk or in braided according to customer's requirements |

1. The aluminum-clad nickel strips are first welded on the aluminum row, and the pure nickel strip is welded.

2. The two materials are combined into one. The welding material is made of aluminum-nickel strip on one side and nickel on one side. This requires only one weld on the aluminum plate.

3. Directly on the aluminum row of composite strips or all nickel strips (0.15 ~ 0.25 thick) by machining or corrosion method, remove the aluminum on the nickel and then stamp.

★★ In addition, aluminum can be replaced with copper according to customer's special requirements for better performance. ★★

![]()

1. Lightweight design, through 7000 pieces of 18650 combination, the connection row weight is reduced by 8KG.

2. Good spot welding effect, lower internal resistance, longer discharge time of battery pack and firmer spot welding of battery

3. Preferential price, stable delivery time and large supply.

4. The industry has matured and the product has undergone 3 generations of evolution.

5. High product stability.

6. The packing way can according the customers requirement

![]()

For mobile power battery, mobile phone battery, 18650 battery pack, soft battery pack, etc

![]()

![]()

1. Are you a manufacturer or a trading company?

We are a manufacturer, engaged in the processing and manufacturing

of nickel, nickel belt, bus bar and plastic bracket. We have a

factory in Yixing, China. It's 16 years old.

2. How to ensure your printing quality?

We use Japanese wire machine tool to make mould, with special mould

manufacturing department, mould assembly workshop, dozens of

high-speed stamping equipment. Copper nickel laser welding

workshop. Adopt two-dimensional measuring instrument test

equipment, film thickness measuring instrument, measuring

instrument, projector, metal hardness tester, salt spray tester.

3. How many machines are there in your factory?

The company has 36 high-speed punches, 10 injection molding

machines, 6 laser welding equipment, 3 wire feeders, 5 grinding

machines and 2 milling machines, 1 two-dimensional measuring

instrument, 1 Vivtorinox hardness tester and stretching machine, 1

film thickness measuring instrument and 1 salt spray measuring

instrument.

4. How many quality inspectors do you have?

We have six engineers

50 production staff

10 famous brand inspectors

5. What are your quality assurance terms?

We complete the production cycle in 7 working days.

Delivery within 3-5 working days.

6. Ensure all products comply with relevant international and

domestic laws, regulations and technical standards

7. Principle of confidentiality

For the customized mold products of the buyer, we will keep the

engineering documents and materials confidential and not disclose

them to other customers. Ensure that all products do not infringe

the intellectual property rights of third parties

|